to replace fossil fuels to power the planet with local sources.

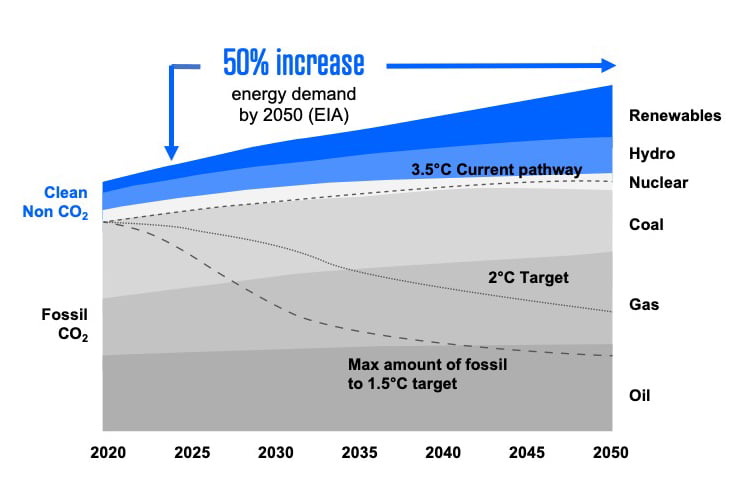

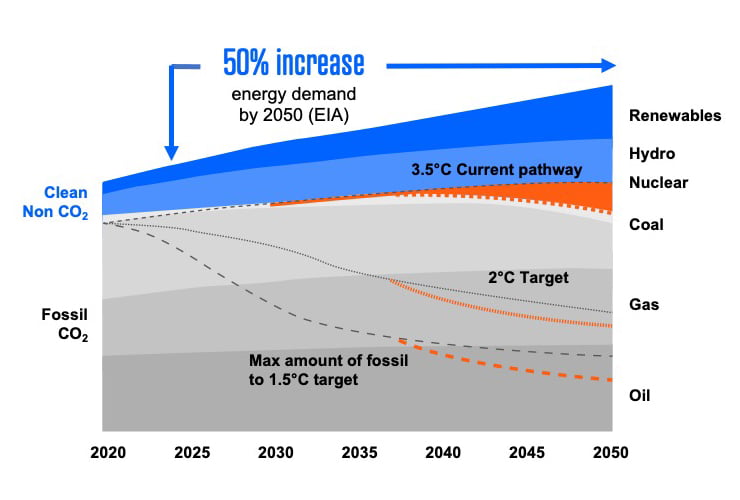

The current path to a 3,5 degree increase in Earth’s temperature leads to a climate disaster. The world must unite behind the call for a reduction in carbon emissions because energy generation demands can no longer be supplied by burning fossil fuels.

A green transition is underway and traditional renewable energy sources are the solution, but to tackle the size of climate change a unique solution with global impact is needed.

A robust technological revolution is rolling out to replace fossil fuels on a large scale because small changes will not help.

In order to make this energy generation transition happen; we need to scale up renewable energy sources quickly. If we continue with the current solar, wind, & hydro technologies, we will fall short of the climate change mitigation.

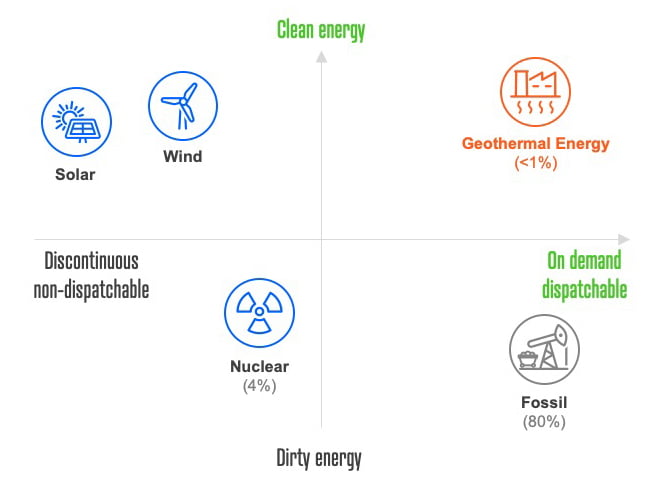

The current state of renewables, primarily wind & solar power, won’t be sufficient to replace the heat, light and mobility we’ve come to expect from traditional fossil fuels.

While useful and promising, wind and solar are transient, interruptible and need back up by fossil sources that significantly devalue the positive impact of renewable use.

Geothermal has the distinct capability of replacing coal-fired power plants on a 1:1 basis, but predictions for geothermal energy’s share of the 2030 energy mix are currently below 1% and that´s not enough.

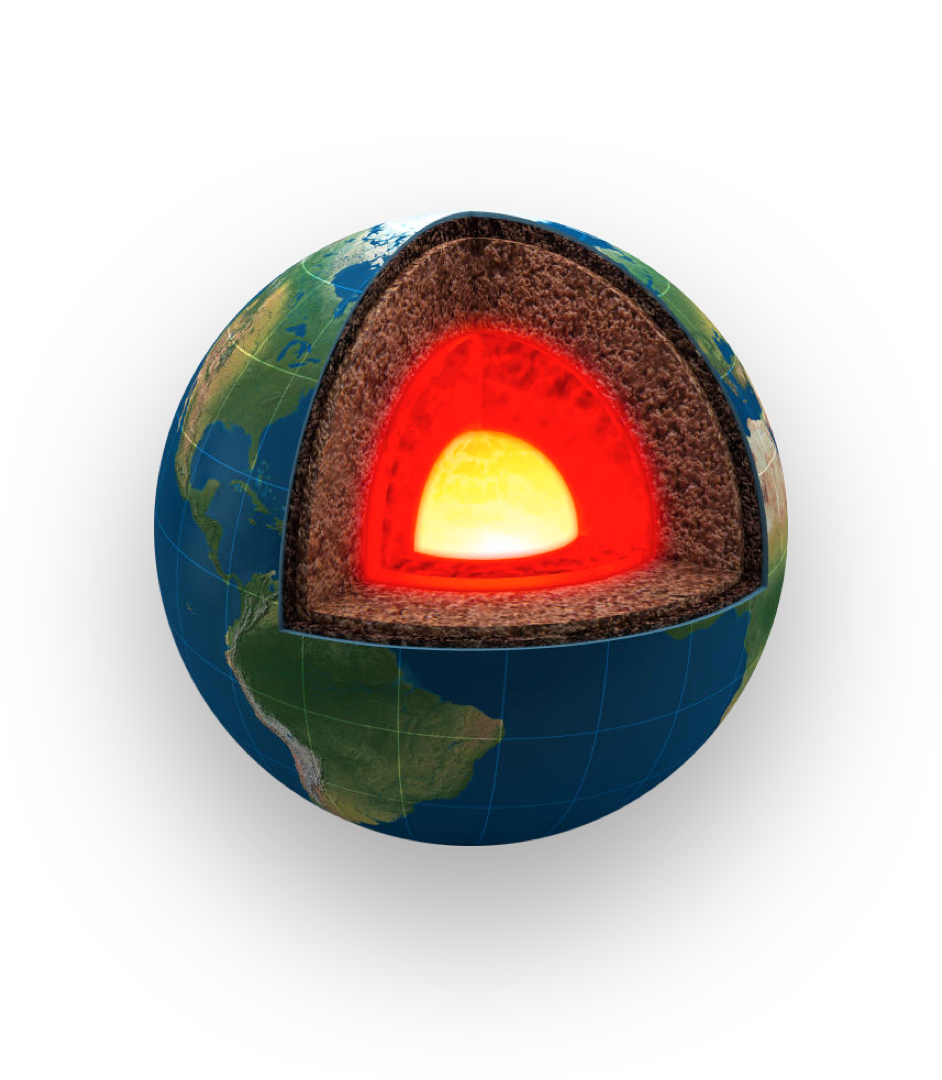

The core of the Earth is the largest, accessible, & most sustainable “battery” with 99% of its volume hotter than 1000˚C. The core is a constant and predictable source of “free” energy that will last for 6 billion years.

To make geothermal energy available and to use it efficiently, it´s essential for us, at GA Drilling, to answer the following questions:

Using our expertise in underground Engineered Geothermal Systems, we focus on innovative subsurface methods. In conjunction with our partners, we combine our expertise with the proven construction of scalable surface infrastructure.

Our solutions are a synergy of:

Benefits of ultra-deep geothermal energy at glance:

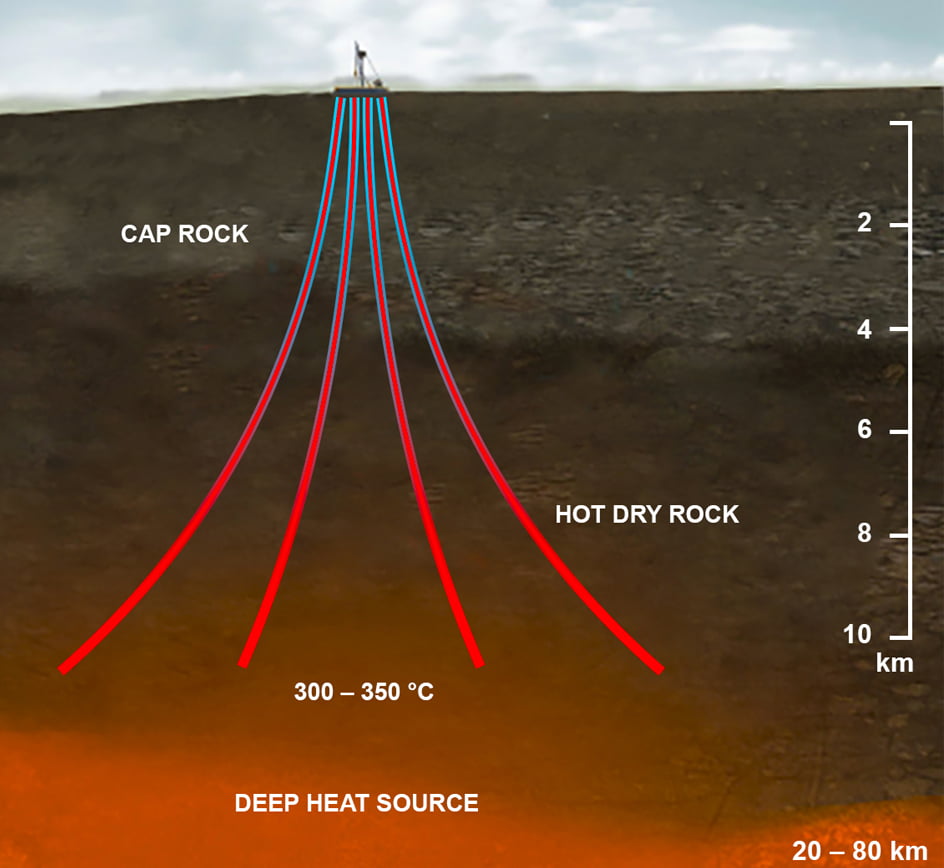

Our intelligent drilling platform PLASMABIT® overcomes all current deep-drilling challenges. With our unique technology, we can drill to the previously prohibitive depths of up to 10 km & unlock clean, inexpensive, baseload geothermal energy anywhere.

By combining our PLASMABIT® solution with conventional off the shelf modular systems, in conjunction with engineering, procurement, & construction partners we will deliver ultra-deep geothermal energy at a low cost anywhere.

By accessing extremely high temperatures PLASMABIT® will unlock a cascade of applications, which can turn geothermal power into the most versatile, constant, & least expensive source of energy available.

Our ultra-deep geothermal solution will promote local production, self-sufficiency, resiliency, & avert the climate crisis.

Get in touch with us.

Partnership or investmentThis site uses cookies to provide services, personalise ads and to analyse traffic. You consent to our cookies if you continue to use our website. More info

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.